Why Inconel 625 Mesh is a Game-Changer for Tough Industrial Jobs

Why Inconel 625 Mesh is a Game-Changer for Tough Industrial Jobs

Blog Article

If you’ve ever worked in environments where heat, corrosion, and pressure are part of the daily grind, you know that not all materials can handle the heat—literally. That’s where Inconel 625 mesh steps in like a superhero.

In this post, we’re breaking down why this high-performance mesh is becoming the go-to choice across industries. Whether you're in aerospace, marine, chemical processing, or power plants, this stuff can take a beating and keep on performing.

So, What Exactly Is Inconel 625 Mesh?

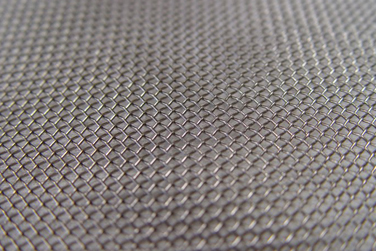

In simple terms, Inconel 625 mesh is a strong, flexible mesh made from a special metal alloy that’s built to thrive where others fail. The alloy itself—Inconel 625—is a nickel-based superalloy packed with chromium, molybdenum, and niobium for added muscle.

When woven or welded into mesh, it creates a material that’s both incredibly tough and surprisingly versatile. Think filters, screens, support structures—anything that needs to survive extreme conditions.

Why Is Inconel 625 Mesh So Special?

Let’s get into what makes this material such a heavy hitter:

Corrosion Resistance: Saltwater? Acids? High-pressure steam? No problem. Inconel 625 shrugs it all off.

Heat Resistance: Withstands temperatures up to 1000°C (1832°F) without losing strength or structure.

Strength + Flexibility: Tough under tension, resistant to cracking, and still easy to shape into custom mesh sizes.

Oxidation Resistance: Holds up even in high-oxygen environments.

It’s basically the material equivalent of “built different.”

Where Is Inconel 625 Mesh Used?

This mesh shows up in more places than you might think. Here are some common (and cool) applications:

-

Aerospace: Heat shields, engine filters, thermal insulation

-

Marine: Offshore oil rigs, seawater filtration, underwater piping

-

Chemical Plants: Acid-resistant filters, reactor linings

-

Power Generation: Steam turbines, heat exchangers, nuclear facilities

-

Environmental Systems: Advanced air and water filters

In short: if the environment is harsh, Inconel 625 mesh is probably there.

What Should You Consider Before Buying?

Before placing an order, think about:

-

Mesh size: Finer mesh for filtration, wider for structural use.

-

Wire thickness: Thicker = stronger, but with less open area.

-

Weave type: Plain, twill, or Dutch weave for specific performance needs.

-

Finish: Pickled or annealed based on your end-use.

Pro tip: work with a supplier who knows what they’re doing and can guide you to the right spec.

Final Thoughts: Is Inconel 625 Mesh Worth It?

If your project demands strength, safety, and long-term performance, then yes—Inconel 625 mesh is absolutely worth it. It’s trusted by engineers, scientists, and fabricators around the world for a reason.

It might not be the cheapest option, but it’s the smartest choice when failure is not an option.

About the Author

Wiremeshes is passionate about helping businesses find the right material solutions for tough challenges. We specialize in high-performance alloys like Inconel 625 mesh, and we’re always happy to help with technical support or custom orders.

Contact - 9903647111

Email - wiremeshes1@gmail.com

Website - https://www.wiremeshes.com/

Report this page